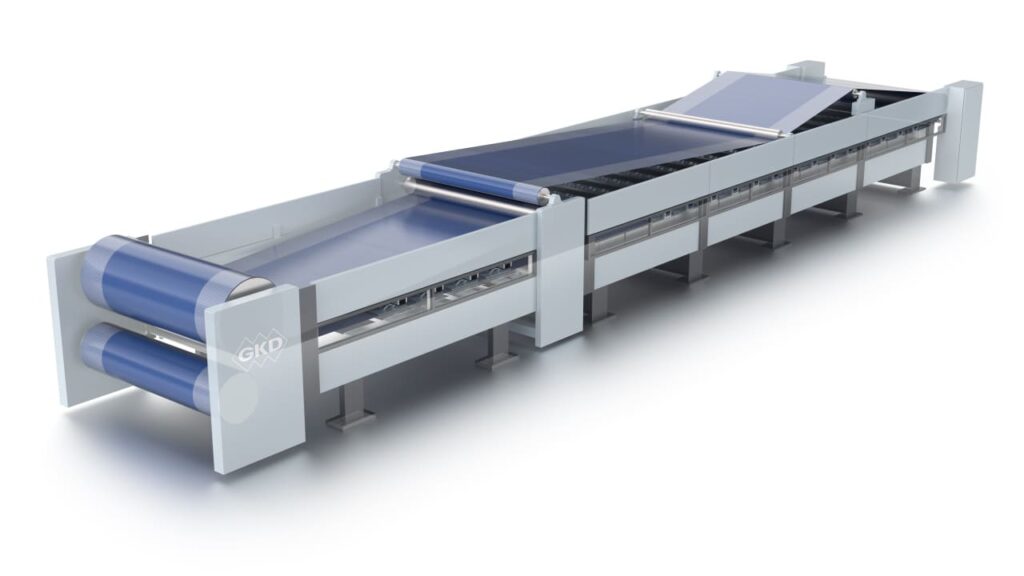

With the BLUEBACKER ECO GRIP SC, GKD – Gebr. Kufferath AG presents a new generation of drum lagging for corrugated board production. This innovative product features an intelligent combination of mesh structure and full-surface polymer layer for optimum running properties when used with all GKD doublebacker belts.

The BLUEBACKER ECO GRIP SC was developed to act as a complete supplier for the double facer unit on corrugators and to eliminate the known disadvantages of drum laggings available on the market. At the heart of the innovation is the German Innovation Award-winning BLUEBACKER mesh.

The most important advantages at a glance

• Full-surface polymer layer: High degree of concentricity of the drum lagging due to high fitting accuracy (form closure) as well as an endless splice without marking.

• Simplified installation: Clean and quick installation that requires no drilling or special tools and therefore no screws or rivets, so that the roller is not subjected to more stress than necessary. The solvent-free assembly also protects the health of employees.

• Improved protection: Corrosion protection for the drum and prevention of twisting of the drum lagging during operation.

Rubber, silicone and self-adhesive laggings with and without clipper are currently used in corrugated board production. What they have in common is that they either can damage the bluebacker belts or the drums of the corrugators in the long term, or cause problems during installation and deinstallation. The BLUEBACKER ECO GRIP SC combines the advantages of current drum laggings and reduces or avoids their disadvantages. The innovation from the world market leader from Düren consists of an intelligent combination of mesh structure and full-surface polymer layer, which ensures optimum running properties in conjunction with all GKD doublebacker belts. No solvent-based adhesives or drill holes are required for installation. The innovative drum lagging reduces the slip between the drive roller and corrugator belt and ensures reliable anti-twist protection thanks to the high pre-tensioning force on the roller shell – without any mechanical fixation. The drum lagging is no longer installed in fragments, but as a continuous element across the entire drum width.

Thanks to the Simple Clamping System (SCS), installing the drum lagging is quick, clean and environmentally friendly – without any drilling or solvents. Removal is also easy with own technicians and without special tools.

Another feature of the ECO GRIP SC is its high degree of concentricity, which is guaranteed by the precise fit of the drum lagging. In addition, the full-surface polymer layer provides optimum corrosion protection for the roller shell during operation. The mark-free endless connection prevents the covering from tearing off. The resulting form-fit effect ensures structural harmonization between the surface of the lagging and the belt.

Dominik Braun, Key Market Manager Corrugated & Pulp for Paper at GKD Group: „Following the success of the BLUEBACKER as a corrugator belt for the doublebacker unit, our new drum lagging is the logical next step. Thanks to its properties, the ECO GRIP SC not only offers a durable and sustainable solution, but also demonstrates GKD’s innovative strength and confirms GKD as a solution and development partner. In my opinion, the new ECO GRIP SC has set a new technological standard in the corrugated board industry.“