We possess an extensive portfolio of embossing technologies for you to choose from. With these, a wide variety of embellishment designs can be applied to packaging.

Embellishment technology embossing is mainly used for high-quality consumer goods, confectionery and cosmetics packaging, but of course also in the cigarette industry.

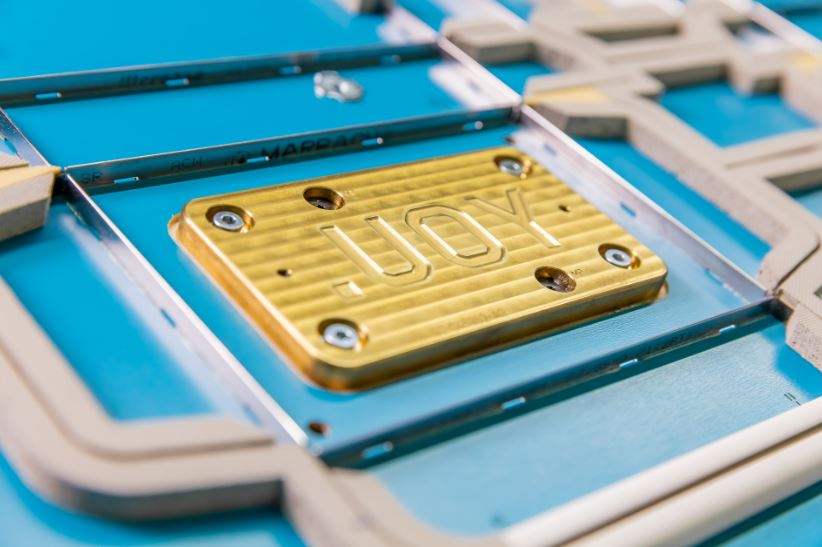

In addition to the two types embossing and debossing, a difference is made between 2D and 3D embossing. With embossing, the cardboard surface is raised, while with debossing it is depressed. 2D embossing is embossing on an embossing plane, whereas 3D embossing, on the other hand, is implemented in several stages, so that embossing takes place on several levels. Another option for packaging finishing is hotfoiling. For this type of embossing a heated hot foil tool transfers foil to a paperboard sheet under high pressure. For high-end packaging with particularly high demands on finishing, a combination of embossing and hotfoiling is often used.

Marbach industry manager Bernhard Reisser: “We have the advantage of being a full-range supplier: We supply embossing and cutting-dies from one source. This way we can offer our customers the right embossing solution and so fulfil their every requirement. Of course, it is always important with embossing that the embossing perfectly matches the print image. Here we have special solutions for our customers – for both embossing and hotfoiling – which not only ensure that the register is perfect, but also that set-up times are as short as possible. Thus ensuring maximum performance when using embossing and flawless packaging at the point of sale.”

There are many different factors to consider when embossing paperboard. To support you in finding the right embossing application, we have created a whitepaper that covers embossing in depth. It also explains what users should look for when choosing embossing designs and embossing plate materials.