DS Smith Tecnicarton and ZICLA have collaborated to jointly develop an innovative self-assembly packaging solution that is made entirely from fibre-based corrugated cardboard materials and intended to provide the maximum protection for smart bike-lane separators and their electronic counting components.

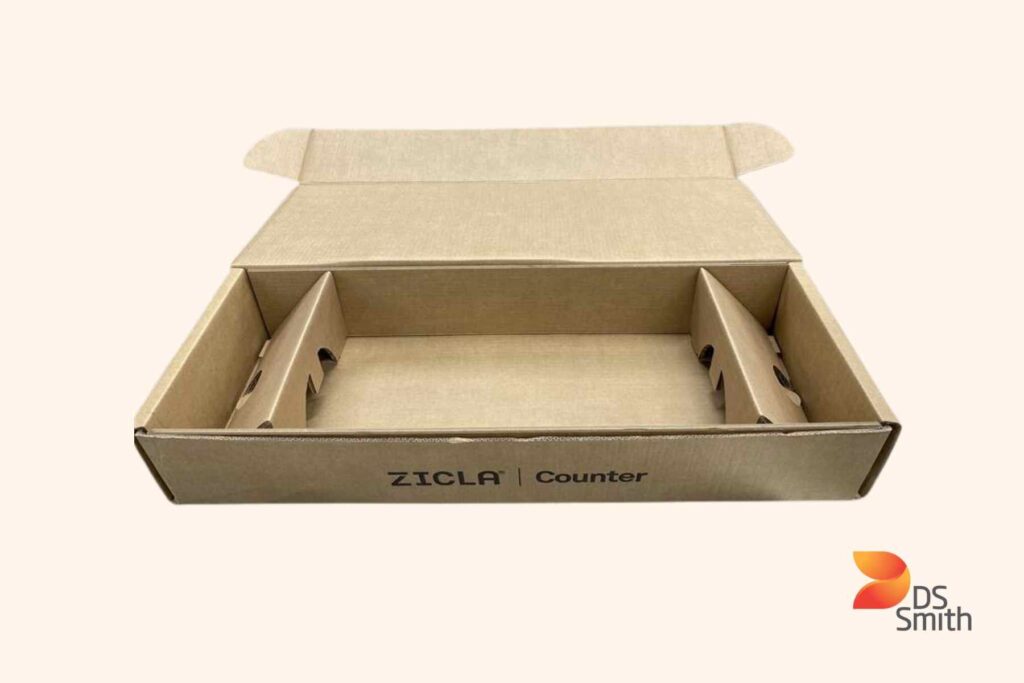

The 100% sustainable packaging consists of two corrugated cardboard elements including an outer box with a tab-locking system to eliminate the need for adhesives or staples and allow for fast and secure assembly. The second component is an internal positioning insert that has been precisely adapted to fit the oval geometry of the product, and is expertly designed to secure into the corners of the corrugated structure in the place of traditional screws. The inserts also ensure that the electronic product inside is secured and fully protected from friction and damage during transportation.

Single packaging format

The packaging solution for ZICLA is in a single packaging format that can accommodate two different product models – each with distinct geometries and dimensions and with a standardised design. In addition, the number of packaging references required to ensure consistency and compliance with industry standards has been reduced. The packaging and palletisation process is simplified with less space required for storage and transportation, and the new packaging is effective in reducing costs, optimizing product protection and logistics efficiency across the entire supply chain.

Antonio Cebrián, Sales Director at DS Smith Tecnicarton:

“Our collaboration with ZICLA demonstrates a clear example of how an innovative packaging design can turn a technical and logistical challenge into an efficient, sustainable and scalable solution. We have worked closely together to develop packaging that both protects a high value-added technological product and effectively optimises an entire supply chain. This project highlights DS Smith Tecnicarton’s ability to be a strategic partner in the development of our advanced and future-oriented packaging solutions”.

The ZICLA packaging design is made to measure and bespoke, and the DS Smith Tecnicarton team applied advanced 3D engineering tools and expertise to create precise visualizations of the final concept. The team also conducted a detailed evaluation around key performance objectives, ranging from handling and storage, assembly, supply chain optimization, packing, picking, and transportation to inform their approach.

Lain Guio, Chief Operating Officer at ZICLA:

“Our new packaging solution represents an important step forward in ensuring the protection of our smart counting separators during transportation and in reinforcing our commitment to sustainability and the circular economy. Our commitment to reducing the environmental impact of our services is fully aligned with our values as a specialist in urban mobility solutions manufactured from recycled materials. Our collaboration with DS Smith Tecnicarton has been essential in achieving an efficient, safe and value-aligned solution.”

The DS Smith Tecnicarton and ZICLA packaging solution received a Liderpack 2025 Award in the Best Packaging in the Electronics, Imaging and Sound category.

Through its purpose of Redefining Packaging for a Changing World and a company-wide and target-led sustainability strategy, DS Smith is committed to leading a transition to the circular economy and to delivering innovative sustainable packaging solutions for its customers worldwide.