In today’s fast-moving and volatile world of package printing, the market leader in surface treatment, Vetaphone, continues to pioneer its offering with a package of service and support to meet customers’ expectations.

According to Anders Dueholm, Support and Spare Parts Manager at Vetaphone, the best manufacturing suppliers take a 360° view of their customers. It’s no longer sufficient to sell, supply and install technology, the responsibility goes further. This is especially the case with an ancillary process like surface treatment, which is often required, but less often understood.

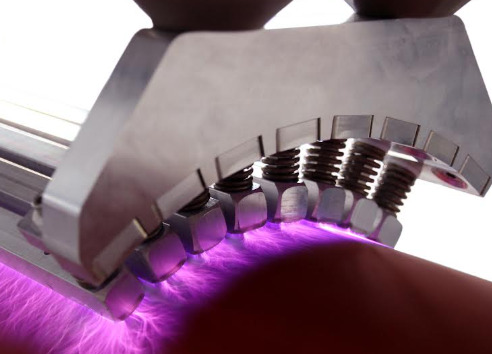

“To many people involved in package print production, the corona treater is a ‘set and forget’ element in the overall line, and modern systems are more reliable than their predecessors – but all technology requires care and maintenance, and the corona unit is often forgotten until it causes a problem,” he explained.

In a market sector where high-speed, high-tech, and high-cost technology works hard to keep pace with demand and at the same time show a profit, reliability and the reduction of expensive downtime are major considerations. And this is where a planned program of ongoing support makes all the difference because it builds customer confidence by ensuring consistent performance.

“Our Preventative Maintenance Contracts offer predictable costs for the user, including discounted parts and reliable technical support to resolve any issues. This support is provided locally in person or remotely on a 24-hour basis, and the service includes scheduled visits organized and carried out by fully trained staff,” he added.

Vetaphone tailors its contracts to suit different requirements. For example, some users do not have their own in-house maintenance team, but some do, others are users with multiple units but are lacking in technical knowledge about corona, while some, known as ‘high-end’ users, require regular inspections to verify the operational condition of the equipment and its safety. No single planned program could cover these varying needs, so Vetaphone builds in flexibility as appropriate.

From the user’s point of view, the benefits are obvious: a reduction in emergency and expensive downtime, optimal and consistent performance of the corona system, 24/7 access to technical specialists for troubleshooting, and lower cost spare parts.“Many users only think about preventative maintenance once the warranty has expired, but this is a mistake. What all converters need is maximum efficiency, and this is best achieved by allowing production personnel to focus on production, not worry about maintenance,” he said.

And the benefits work both ways. User feedback since launching the scheme has been extremely positive and enabled Vetaphone to identify the most frequent issues and be more pro-active in these areas, while overall it has provided the company with a better view of the general optimization of its technology. For a company, where ongoing R&D is an essential part of its DNA, all inputs from day-to-day commercial operations are valuable.

“We live in a world of complex technology and its influence on our daily lives is only going to increase. That’s why it is important to ensure that we derive the maximum benefit from it, and this can only be assured with regular care and maintenance. So why not pre-plan it? It will save money and heartache at the end of the day!” he concluded.