Esko has launched Cape Pack Prime, a new packaging-driven sustainability solution that helps packaging converters successfully reach their own sustainability targets.

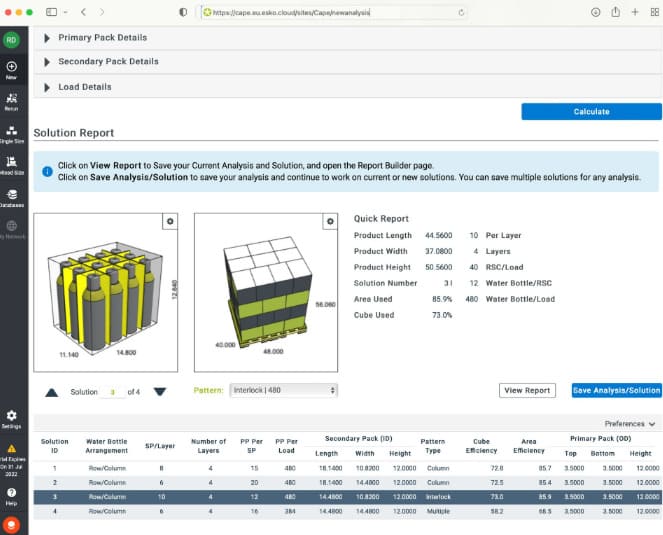

An extension to the popular Cape Pack software for packaging and logistics optimization, Cape Pack Prime is an easy-to-use, cloud-based platform that uses real world product models to accurately calculate optimized packaging and palletization solutions that drive down costs and help customers meet their sustainability KPIs.

“As climate change concerns intensify, sustainability is no longer a choice, but a necessity across the packaging value chain,” said Esko Marketing Director Jan De Roeck. “Consumers are becoming increasingly environmentally conscious and exerting pressure on companies to adopt less impactful practices, while increasing regulations are applying pressure on brands to take more responsibility for their broader environmental impact.

“While both brands and their suppliers are under increasing pressure to deliver on packaging sustainability, packaging design and development is often undertaken in silos where components are created by different people, in different companies, and at different times,” he said. “This fragmented information means it is challenging to optimize packaging for sustainability and to track progress against KPIs.”

Cape Pack Prime features a new integrated carbon emission calculation capability, developed in partnership with CarbonQuota®, which enables brands and packaging converters to accurately measure and reduce their environmental impact through automated carbon footprint calculations, helping them meet sustainability goals and comply with evolving regulatory requirements.

New Cape Pack Prime enables packaging and label converters to:

• Create and evaluate palletizing solutions in seconds, for maximum efficiency and minimum waste

• Create CAD assets using dimensional pack data from an actual product by importing 3D models as the primary pack to reduce the empty space in your packaging

• Evaluate case and pallet solutions for compression strength and economic factors to identify lightweighting opportunities for the best fitting solution

• Automatically generate right-sized CAD files, dielines, 3D models and reports for the chosen solution, increasing project speed and decreasing costs

• Reduce shipping costs by an average of 10% while protecting products from damage

• Instantly calculate pallet loads and shipping quantities for knocked down flat product and shipping containers enabling box converters to obtain efficient and accurate transportation estimates

• Optional integration with Life Cycle Analysis systems for carbon footprint calculations

“Cape Pack Prime actually enables users to integrate automated carbon footprint reporting within the Esko workflow platform,” said Jan. “This new capability and transformative approach further enriches the Esko ecosystem and makes it significantly easier for customers to effectively calculate the carbon footprint of any package or label design.

“Cape Pack Prime offers a complete design and palletization solution that automatically creates all files and metadata for a packaging system,” he added. “This groundbreaking platform eliminates any disconnect by standardizing methodologies, streamlining data collection, and providing verified environmental impact measurements that both brands and converters can trust.

“To do this at the very start of the packaging design process paves the way for the most sustainable packaging solution for the end-user,” he said.