Pioneering sustainability and integrating innovation into legacy systems are among the most pressing challenges facing food and beverage manufacturers today. Encouragingly, the direction of travel is clear: as the world moves towards a more circular economy, the market is increasingly turning to paper as a solution. And Tetra Pak recently made important step in its paperisation journey.

Paper-based packaging, in particular, is gaining momentum in the packaging industry, with ‘renewable resources that reduce CO₂ emissions’ considered the most important feature of a sustainable package. Food and beverage manufacturers are looking to packaging and processing suppliers to support them in this transition, with 65% citing new product development as the key to adopting more sustainable practices.

While aseptic cartons already contain at least 70% paperboard, caps and closures have until now depended on polymers for their durability and performance. Life Cycle Assessment studies show that beverage cartons already have a lower carbon footprint than plastic or glass bottles or comparable metal packaging, so by increasing renewable content, a paper-based cap can improve that profile even further.

As the industry looks to shift towards paperisation, the new cap marks another step in our ambition to further decrease the carbon footprint of our packaging, all while maintaining food safety.

Real world testing

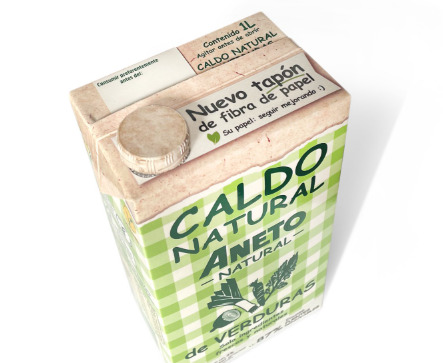

In April 2025 consumers have already had a chance to try the new paper-based cap on a beverage carton. Earlier this year, we worked with our long-time customer Aneto to launch a trial in Spain, offering vegetable broth in Tetra Brik Aseptic 1000 Mid cartons with the groundbreaking cap replacing the usual plastic closure.

Collaborating with a forward-thinking company like Aneto has been key to introducing this breakthrough technology; they are committed to innovating for the circular economy, and together we’ve shown what’s possible when sustainability and innovation come together.

The cap features a two-step screw mechanism; the screw part is moulded from paper fibres, while the neck, pull-ring and inner plug are made from plant polymers derived from sugarcane, which is also a renewable material. This replaced the traditional plastic closure and increased the paper content of the total package. Combined with the sugarcane-based polymers, the total renewable content is ~87%.

In developing this product, our team was tasked with more than a simple material swap. The cap must endure moisture, transport stress, and temperature fluctuations — challenges rarely tackled with paper-based closures.

With the first beverage carton with paper-based cap on shelves, the Spanish market provided a solid foundation for testing and learning. Hundreds of consumer reviews offered valuable insights into how sustainability advancements are perceived at the point of purchase. This feedback is now helping us evaluate industrialisation pathways and explore options of broader applications of the technology across different cap types.

Inherent circularity

This industry-first innovation is more than just an improvement to the environmental impact of the carton. It could also support the advancement of recycling processes. Research shows that over a third of EU consumers are more likely to recycle if packaging is entirely paper. Moreover, increasing the paper content of the package also makes cartons more attractive to recyclers. Circularity reduces boosts the reuse of materials, aligning with both environmental goals and commercial incentives.

This innovation is a milestone for both Tetra Pak and Aneto, and a broader signal of where the market is heading. It responds to rising demand from both industry and consumers for solutions that reduce reliance on fossil-based materials without compromising food safety, quality or functionality.