C&T Channel Matrix (C&T), the world’s leading manufacturer of creasing matrix, ejection rubber, die-making consumables, and state-of-the-art rubber-cutting machinery, continues to strengthen its offering to the corrugated packaging industry with a range of high-performance products designed specifically for the demands of corrugated board conversion.

As demand grows for robust, sustainable, and high-quality corrugated packaging, converters are under increasing pressure to maintain precision and efficiency across complex production processes. C&T continues to develop and enhance its matrix to tackle common issues, such as cracking, poor registration, board crush, and creasing failure.

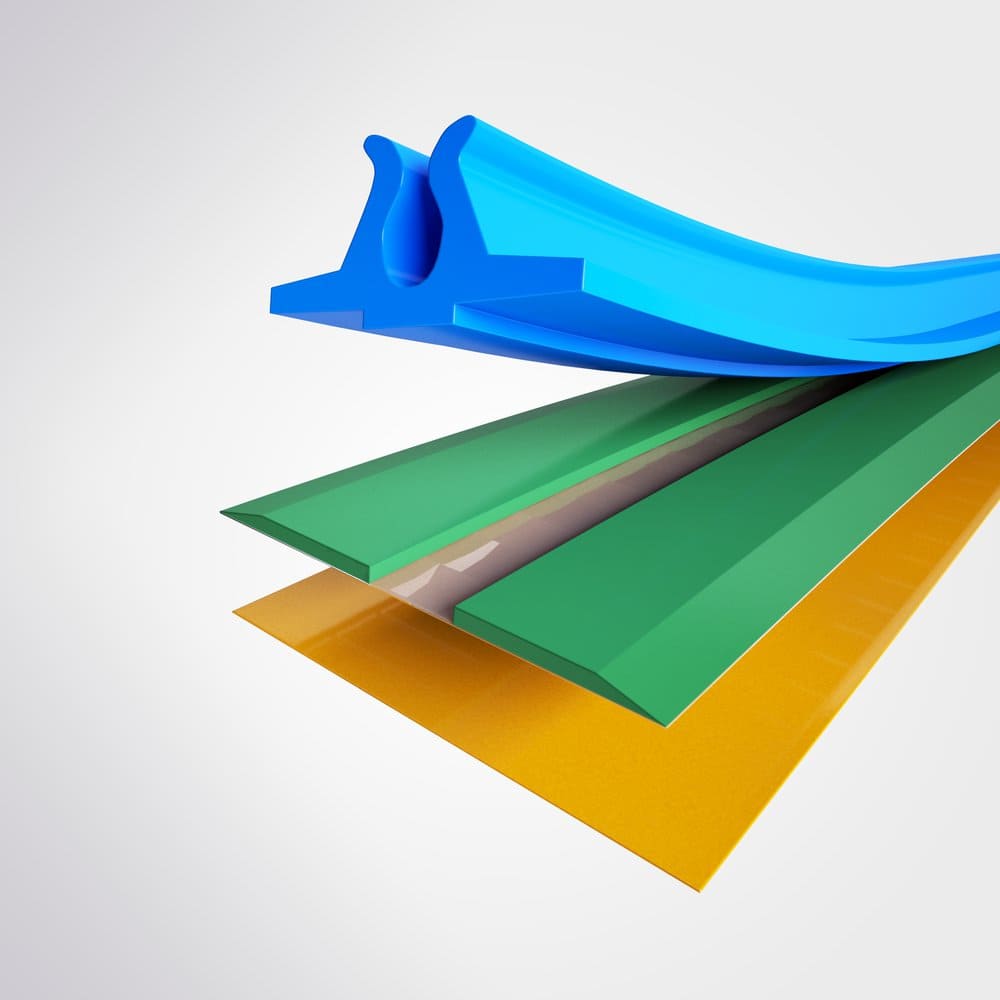

C&T dedicated creasing solution for corrugated packaging, Corrugate Matrix is specifically engineered to address the unique characteristics of corrugated substrates.

Stephen Williams, UK Sales Technical Director at C&T, commented: “Corrugated board comes with its own set of challenges, from varying liner grades to print-heavy litho-laminated applications. Our approach is to work directly with our customers to analyse the entire set-up—board specifications, caliper, crease design—and provide tailored advice on matrix and rubber combinations to deliver consistently accurate and clean creasing results.”

Corrugate Matrix is specifically engineered to address the unique characteristics of corrugated substrates.

Key features of Corrugate Matrix include:

- Wider 20 mm base for improved adhesion to the die plate, reducing movement, poor registration, and creasing failure

- Designed to minimise cracking and knuckling, especially in litho-laminated and recycled liner applications

- Supports clean, consistent creasing even on heavily printed surfaces

- Includes a U Bend sub-range for precise 180-degree folds, ideal for complex packaging designs

“Corrugate Matrix is designed to make corrugated conversion more reliable and efficient,” added Williams. “It enables converters to handle a wide range of corrugated applications—from basic transit boxes to high-end printed packaging—without compromising on quality or productivity.”