Duo UK has been appointed by HellermannTyton, the Manchester-based cable management manufacturer, to develop an innovative packaging solution – the first of its kind in the sector.

The packaging has been designed to prevent moisture damage and product failure during the transportation of cable ties and has eradicated the requirement for a second packaging item.

HellermannTyton manufacturers and supplies a range of products for fastening, fixing, installing, connecting, insulating, protecting and identifying electrical cables and network connectivity solutions. The products, which include plastic, embedded metal and fire-resistant cable ties, must retain moisture within their packaging to prevent them from becoming brittle and snapping.

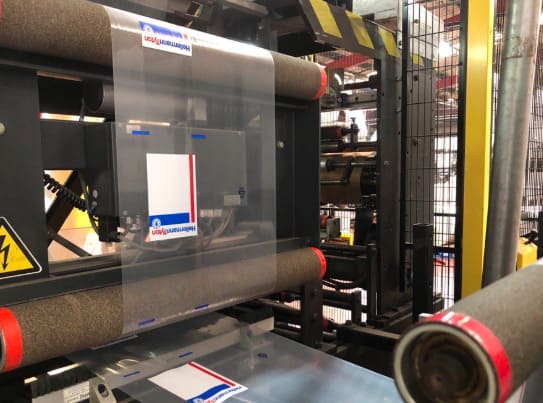

Duo worked closely with Radu Eane, Global Packaging Development Lead at HellermannTyton to create a specialist bag that features an innovative moisture-retaining barrier on both sides of the packaging. Previously, the company packaged and repackaged the cable ties in several different bags to help lock in the moisture and preserve product quality.

Dale Brimelow, operations director at Duo UK, commented: “The new packaging innovation has had an immediate and substantial impact. It has streamlined the packaging process, which has a potential to increase production. Additionally, it has helped remove over 160,000 laminated bags from the supply chain each year, creating a fully recyclable solution with increased efficiency and better cost control. All this has been achieved while enhancing moisture control to better protect products during transit.”

The packaging solution is made using LDPE with 30% recycled content, delivering a fully recyclable solution for HellermannTyton.

Maddie Maudsley, Head of Procurement at HellermannTyton, said: “We have trialled this solution for over a year, rigorously testing it to ensure it worked with our machinery. Through dedication and commitment to create what is an industry-first solution, Duo has helped us to tackle a problem, using their expertise and experience to turn that into a solution by understanding our needs and manufacturing capabilities. As a result, it has delivered unbelievable results.

“As a global company, working alongside locally-based suppliers is extremely important to us and supports our wider sustainability goals as a business. What’s more, the ability to stock hold with Duo is invaluable, especially given the scale of machinery we operate on-site.”