The HL-60 streamlines labelling processes with advanced automation, flexible size handling, and remote monitoring capabilities, ideal for co-packers and small manufacturers

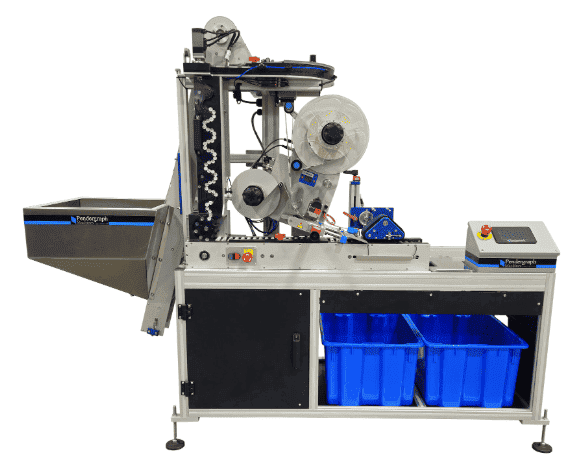

ProSys Fill, a leader in the design and manufacturing of automated filling equipment, highlights the HL-60, a compact yet fully automated labelling system designed to streamline the production of industry-standard cosmetic and product sticks, from lip balm to body care products. Designed and manufactured by ProSys’ exclusive partner Pendergraph Machines, the HL-60 brings together precision, flexibility, and efficiency in a compact machine, reducing floor space while automating key processes such as feeding, labelling, and counting. With the capacity to handle high production speeds and multiple stick sizes, this versatile system is ideal for co-packers and small manufacturers looking for a solution with entry-level pricing, American-made value, and stellar service.

The HL-60 optimizes production environments by feeding, labelling, and counting sticks into totes, all in one compact machine. This makes the system particularly well-suited for tight production areas, allowing manufacturers to maximize their space efficiency without compromising productivity. Additionally, the HL-60 features an automated stick feeding system, allowing the machine to load sticks at high speeds, reducing manual intervention and operator errors. This results in faster production times compared to manually loaded systems, a significant improvement for operators seeking to enhance throughput.

At the heart of the HL-60 is the high-quality Herma labelling head, renowned for its accuracy and longevity. This component ensures consistent, precise labelling, a critical requirement for manufacturers who depend on long-term reliability in their equipment. The HL-60 also incorporates automated counting and tote switching. The dual-tote counter features a customizable count range, allowing operators to perform other tasks while the machine counts products and automatically switches to an empty tote once a tote is full. The system’s design allows for easy access to tote changes from either side, further improving workflow efficiency.

The HL-60 is controlled by an advanced Unitronics PLC/HMI system, which not only simplifies machine operations but also offers remote monitoring capabilities. Through Ethernet or Wi-Fi connectivity, operators and production managers can access the system via an app-based dashboard. This allows them to receive real-time notifications on their mobile phones or tablets, making it easier to manage production processes remotely.

One of the standout features of the HL-60 is its flexibility. It is capable of running multiple sizes of round, industry-standard sticks, ranging from .15 oz lip balm sticks to .50 oz face and body sticks. This versatility makes it ideal for manufacturers handling a variety of product sizes. Furthermore, the compact design allows multiple HL-60 units to be operated by a single skilled operator. In a 10′ x 10′ space, up to four machines can be managed at once, producing as many as 240 pieces per minute, offering an exceptional combination of productivity and labor efficiency.

The HL-60 is particularly well-suited for co-packers and small manufacturers who require flexibility and fast, user-friendly changeovers to accommodate both small and large orders. Its intuitive design is also an attractive feature for engineering managers, maintenance personnel, operators, and facility managers who value efficiency and ease of use in their equipment.