We are known on the market for its innovative solutions for packaging production. In the corrugated board sector, one of the latest Marbach technologies is the DZL|plateXL, a zone levelling solution for large format die-cutting machines. This ensures significantly reduced make-ready times.

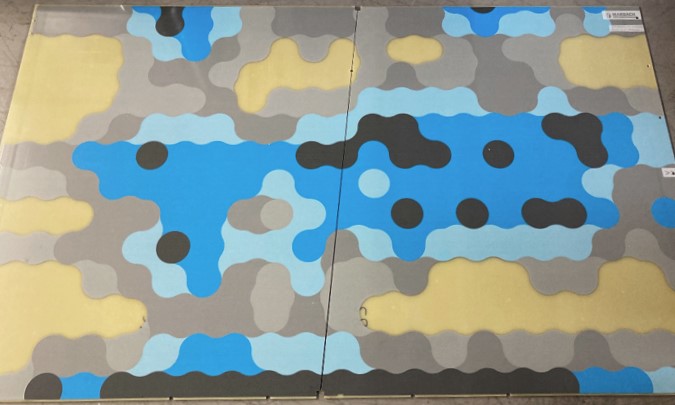

Unevenness in the cutting platen is often caused by wear and tear on the machine. This is a common problem in packaging production, which affects the processing speed as well as the quality of the blanks. Ralf Nuyken, industry manager at Marbach, explains: “The DZL|plateXL has been specially developed for large format corrugated die-cutting machines. It consists of a two-part protection plate that is individually adapted to the height profiles of the respective die-cutting machine. Once inserted, the DZL|plateXL ensures permanent and efficient zone levelling. This compensates height differences in the cutting platen, resulting in optimum pressure conditions during die-cutting and significantly reduced make-ready times for each job. Productivity in packaging production is increased.”

The little brother of the DZL|plateXL is the DZL|plate, which was designed for smaller-format cardboard packaging machines.