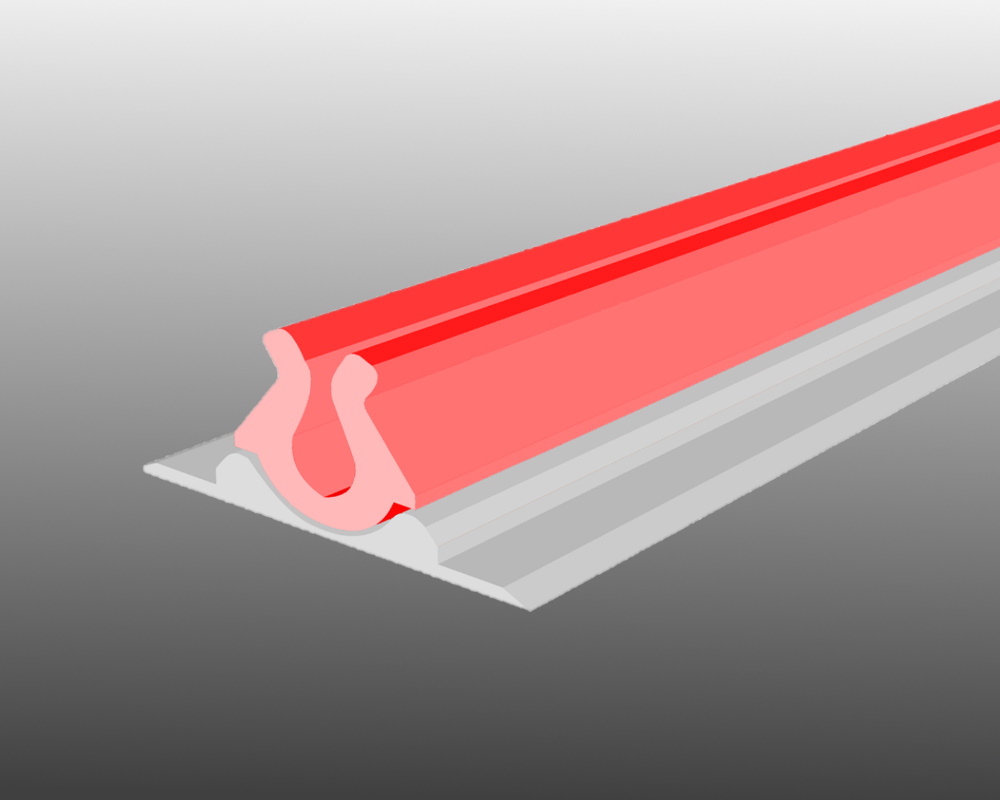

The hallmark feature of 8 PRINT lies in its rounded channel design. This unique channel enables the seamless and precise die-cutting of corrugated board, spanning from microflute to triplewall, without inducing any breaks or cracks. This meticulous process guarantees a polished and professional finish, all while minimizing any wastage during production.

Beyond its exceptional die-cutting prowess, 8 PRINT exhibits remarkable resilience, rendering it well-suited for high-volume production runs. Its robustness ensures optimal punching precision and unwavering reliability, ensuring consistently impeccable results.

Fashioned from a singular milled piece, 8 PRINT boasts unparalleled quality and longevity. Its configuration is meticulously honed for corrugated cardboard, delivering outstanding performance, even when aligned with the flute direction. When users are selecting the appropriate 8 PRINT matrix, it is imperative to factor in the width and thickness in relation to the flute direction, as well as the grammage of the paper. This thoughtful consideration ensures the utmost in performance and results.

Simon Shenton, Managing Director of C&T, expressed enthusiasm about the introduction of their new matrix, 8 PRINT, to the market. He noted, “This exceptional fiber-based matrix is purpose-built to cater to the demands of corrugated board conversion. We already offer a diverse range of specialized matrices for the corrugated sector, including Corrugate, Hinge, and Reverse Bend. The addition of 8 PRINT further bolsters our portfolio and underscores our commitment to meeting the evolving needs of our customers.”