Labelexpo Europe, Brussels, Fujifilm launches LuXtreme, a new LED UV curing system that allows any traditional flexographic press to be converted to LED UV curing, resulting in enhanced label production on a narrow web press.

LuXtreme offers high speeds of up to 200m/min, along with better substrate stability, resulting in enhanced productivity for printers. Additionally, the system offers 30-50% higher radiant intensity than competitive LED curing systems, up to 25W/cm².

The system uses 30-60% fewer LED lamps to achieve the same radiant intensity as other comparable systems. This results in better registration and less material distortion. improving the overall quality of printed materials. The energy savings this offers compared to conventional UV systems, as well as competitive LED curing systems, are significant, with both material usage and waste also significantly reduced, enhancing overall productivity and making the system a highly sustainable mercury-free solution.

Due to the reductions in power required for the LED UV lamps, cost savings can be made across the production process. Additionally, the lower maintenance, downtime and make-ready times required to support the system also lead to a lower number of replacement parts required over its lifecycle, and lower associated labour costs.

The working environment for operators is also improved, with many undesirable factors eliminated or reduced, including heat from conventional UV and air cooled LED lamps, ambient noise and odours.

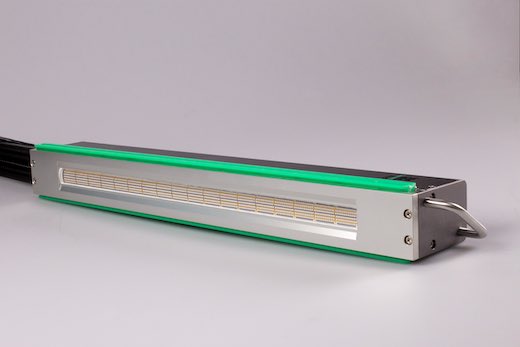

The system offers up to 50,000 hours LED life and up to a 720mm lamp length, scalable in 24mm steps. An LED adaptor allows easy integration on to existing mountings.

Manuel Schrutt, Head of Packaging, Fujifilm EMEA comments: “We are excited to be bringing such an innovative and unique solution, alongside other innovations such as LED IFDC inks, to the labelling market. Sustainability is at the forefront of our processes and product development, and this launch demonstrates our commitment to providing high quality solutions that are beneficial for the environment, while providing customers with improved efficiency and productivity and a pleasant work environment. Labelexpo provides the ideal opportunity to launch this to the market and we look forward to showcasing the product to existing and potential customers.”