VegoPak was founded to tackle plastic pollution head-on. Can you share the moment or insight that first inspired the creation of your bio-based polymer?

The idea for VegoPak first emerged in 2019 in Australia as part of a Year 9 sustainable business project. It was inspired by growing concern over microplastics breaking down in the environment and entering our oceans, where they pose serious threats to marine life and ecosystems. I personally wanted to tackle this issue and find a practical solution that could help reduce the harm caused by plastic pollution. After completing my GCSEs and A-levels in the UK, I took a gap year to focus intensively on research and development, during which we successfully created our sustainable bio-polymer.

Sustainability and practicality often clash in product design. How did your team strike the balance between environmental responsibility and real-world performance?

We are proud of how we have been able to combine sustainability with real-world performance. From the beginning, our goal was to create a material that could match the strength and versatility of conventional plastics while being genuinely eco-friendly. Through careful R&D and iterative testing, we refined the polymer to be durable, flexible, and reliable. At the same time, we designed every stage of its lifecycle to minimise environmental impact. The result is a solution that proves it’s possible to be both responsible and practical without compromise.

Developing a bio-based material that matches plastic’s durability sounds like a huge scientific leap. What were some of the biggest challenges or breakthroughs during R&D?

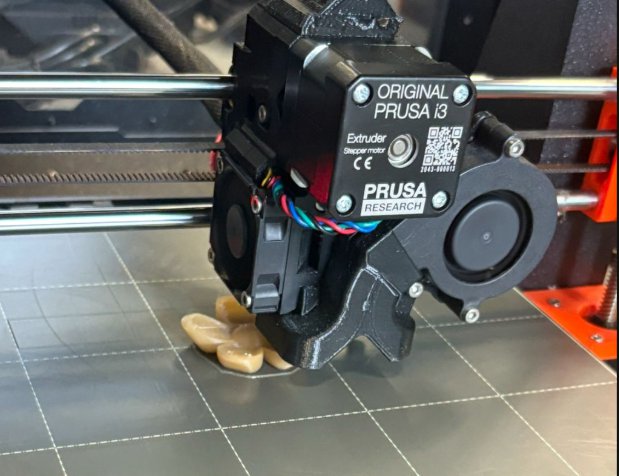

Our major breakthrough came during the manufacturing testing stage, particularly with 3D printing. We experimented with both 0.8 mm and 0.6 mm nozzles, both performed exceptionally well. The 0.6 mm nozzle is typically used for more intricate designs, making it a more advanced form of 3D printing. The attached image of the 3D-printed flower clip demonstrates this capability: as you can see, the design incorporates detailed elements, varying heights and overhanging structures, showcasing the precision and versatility of our material. The biggest challenge for the business was time management

How does VegoPak’s biopolymer differ from other bio-based or compostable plastics currently on the market?

VegoPak’s biopolymer differentiates itself from other bio-based or compostable plastics through its combination of mechanical performance and versatility. Many alternatives on the market are limited by low tensile strength, poor thermal stability, or restricted processing options. In contrast, our biopolymer is engineered to match the durability, flexibility, and processability of conventional plastics, including compatibility with advanced manufacturing techniques like 3D printing, extrusion and injection molding. This allows it to perform reliably in a wide range of applications, making it a practical, high-performance alternative to existing bio-based materials.

You mention VegoPak can be used in everything from food packaging to construction materials. Which sector has shown the most enthusiasm or promise so far — and why?

The market feedback so far has been positive across all sectors, time will tell which market has the strongest uptake for VegoPak biopolymer. External market forces are driving behaviour change in the plastic industry and it will be interesting to see which segments adopt our technology to achieve their sustainability goals.

How do you ensure that the sustainability benefits of VegoPak are maintained across the entire lifecycle — from sourcing to end-of-life disposal or recycling?

At VegoPak, we look at sustainability as a whole-life commitment, not just a product feature. From the very beginning, our focus has been to create a material that performs well and leaves a lighter carbon footprint throughout its entire journey — from production to end-of-life.

We have designed our bio-polymer to integrate seamlessly into existing manufacturing systems, helping reduce unnecessary waste or the need for new infrastructure. Beyond production, we are equally focused on what happens after use — ensuring that our bio-polymer can be responsibly repurposed, recycled, or disposed of without harming the environment.

What are some of the common misconceptions or barriers businesses face when switching from conventional plastics to bio-based alternatives?

One of the most common misconceptions businesses have is that bio-based alternatives can’t match the performance or durability of traditional plastics. At VegoPak, we are proving that is not the case. Our sustainable bio-polymer delivers strength, flexibility, and usability comparable to conventional plastics — and it can be manufactured using existing machinery, eliminating the need for capital intensive process changes. Best of all, it achieves this while creating a positive environmental impact, offering a truly practical and scalable solution for businesses ready to make the shift toward sustainability.

Collaboration often drives innovation — are there any partnerships or pilot projects that have been particularly exciting or influential for VegoPak’s growth?

We have been incredibly fortunate to receive the Advanced Materials and Manufacturing Innovation Centre (AMMIC) Grant from Manchester Metropolitan University (MMU). This partnership has been instrumental in accelerating our progress of industrial manufacturing and testing.

Through the grant, we have achieved demonstration of usability across several commonly used industrial processes, these being: injection molding, extrusion and 3d printing. In addition, we obtain exciting results from our mechanical performance testing, such as, tensile, flexibility and impact testing.

Our success with extrusion enabled us to produce sufficient filament to advance into 3D printing trials, where we tested our bio-polymer using both 0.8mm and 0.6mm nozzles. The results were highly encouraging — particularly in terms of bridging and achieving intricate, detailed designs, which clearly demonstrate how our bio-polymer stands apart from existing materials on the market.

One of our first tangible outcomes from this phase was a 3D-printed flower hair clip, created using the 0.6mm nozzle — showcasing the versatility and strength of our material.

The collaboration with Manchester Metropolitan University has validated the performance of our material and enabled us to advance our manufacturing readiness level with greater confidence and precision.

VegoPak’s ethos centres on “innovation driving positive environmental change.” How does that philosophy guide your everyday decisions as a company?

For me, “innovation driving positive environmental change” means constantly asking, “how we can make a real difference through what we develop?” — not just by being sustainable, but by being practical, scalable, and impactful. Every step we take, from testing new ideas to partnering with others, is driven by the goal of creating solutions that work for people and the planet.

Looking ahead, what’s next for VegoPak — are there any upcoming developments or goals that you’re especially excited about?

Our next major step for VegoPak is an exciting transition, we are currently preparing to sell the rights to our biopolymer. After several successful stages of research, testing, and validation, we have reached a point where our bio-polymer technology is ready to scale and make a real impact in the world.

We are now seeking the right strategic partner, or buyer, who can take VegoPak to the next level – someone with the resources, infrastructure, and shared commitment to sustainability needed to bring our innovation to market at scale.