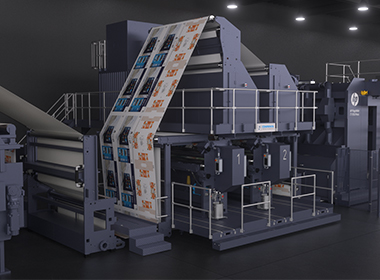

he installation of HP’s PageWide T1195i Press, which will to go into operation at Thimm’s Alzey site in 2024, is already in full swing. Now Thimm is providing an insight into the technical innovations with which the new system combines even shorter delivery times with sustainable printing processes.

The new digital printing system from HP not only impresses with brilliant printing results, but also with faster speeds and more production capacity. As Thimm now announces, the new system will be equipped with the latest generation of print heads: the innovative HP Thermal Inkjet print heads of the six integrated inking systems guarantee consistent print quality even at high speeds. This means that a wide range of print images can be produced for sophisticated packaging designs. At the same time, printing effects typical of digital printing are greatly minimised. This reduces unnecessary waste and thus conserves resources. When it comes to sustainability, the robustness of the individual print heads offering a particularly long service life is also extremely impressive – and this too saves resources. Michael Weber, Head of Strategy at Thimm Group adds: “The digital printing process is very energy-efficient: overall, we consume around 52% less energy in digital printing compared to flexo printing. In addition, we can reduce CO2e emissions by around 26 percent, because the production of photopolymer printing plates is not required in digital printing.”

To produce even more efficiently while preserving resources even more effectively, the packaging manufacturer decided to equip the new digital printing system with two additional inking systems from Conprinta. “Thanks to this addition, we can now also offer our customers spot varnish and full-surface colouring in combination with digital printing in a sustainable way. We save precious resources by being able to apply varnishes in a targeted manner instead of over a large area,” Weber emphasises.

The groundwork for the installation of the new system has already been completed. The next step is to prepare the peripherals and set up the machine. It is scheduled to go into operation in the first quarter of 2024. The new digital printing system is seen as a milestone for Thimm in achieving its digitalisation vision Internet of Packs – the networking of supply chains with the help of packaging.